Jane Bolsover, in her new book Sewing School Basics, gives us the complete rundown on how to make buttonholes. See how to do it, below.

Jane Bolsover, in her new book Sewing School Basics, gives us the complete rundown on how to make buttonholes. See how to do it, below.

If you’re looking for a step-by-step course for first-time stitchers, or a sewing refresher, Jane Bolsover’s new book Sewing School Basics could be the one for you. In it, you can learn how to make your own clothes and home furnishings.

If you’re looking for a step-by-step course for first-time stitchers, or a sewing refresher, Jane Bolsover’s new book Sewing School Basics could be the one for you. In it, you can learn how to make your own clothes and home furnishings.

The first part of the book outlines your sewing kit and which fabrics are suited for which use; the second part of the book is a structured course of 12 workshops, which build from the most basic hand-sewing techniques through to more advanced dressmaking skills.

The projects range from a simple hand-embroidered pillow to a cozy lined throw, and from a shirred sundress to an organdie pleated skirt. Techniques include darts and waist finishes, gathers, shirring and smocking, tucks and pleats, binding, necklines and collars, and more.

A great book with excellent photos and illustrations.

Sewing School Basics by Jane Bolsover is published by CICO Books and is available from all good bookshops or online outlets. For more information, please visit www.cicobooks.co.uk. Distributed in NZ by Bookreps. Extracted with permission.

BUTTONHOLES

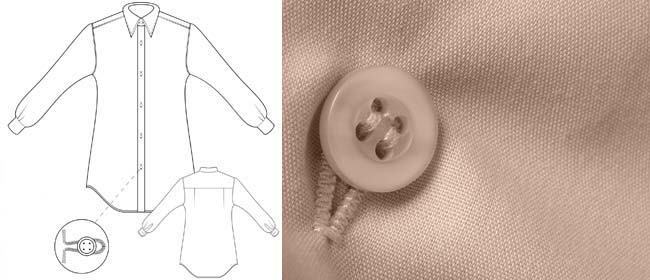

In this book we are looking at machine-worked “square” buttonholes, which are the most popular type. You may come across bound buttonholes, especially on tailored garments such as jackets and coats, but it’s best not to attempt these till you are more experienced at sewing.

The standard buttonhole is basically a slit made through the fabric, with a bar tack at each end, and the edges finished with a machine zigzag stitch. In the past, buttonholes were finished by hand using buttonhole stitch, a special type of blanket stitch with a knot on the raw edge to strengthen it.

Most modern sewing machines offer several buttonhole variations, such as a rounded end for shirts and blouses, and a keyhole shape for thicker fabrics. Check your manual to see what your machine is capable of doing. The buttonhole is stitched through all layers of fabric, and as with attaching buttons, it is advisable to use interfacing to reinforce the area. The buttonhole is not cut until after the stitching has been completed.

Calculating the length

Working out the correct length for a buttonhole is crucial, as it must be large enough to allow the button to pass through easily, but not so large that it won’t hold the item securely fastened.

Buttonhole sizes are normally marked on sewing patterns, and slider or sensor buttonhole feet set the size of the buttonhole automatically when the button is placed in the rear of the foot, but it is still a good idea to know how to calculate the length for yourself.

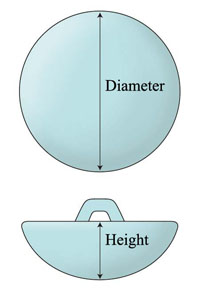

The length of the buttonhole for either a sew-through button or a shank button is determined by the diameter and height of the button.

Add them together, then add an extra 1/8 in (3mm), which allows for the bar tacks at each end.

Marking buttonholes

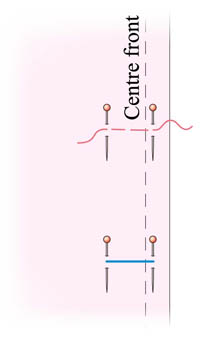

Vertical buttonholes normally sit along the centre front line of a blouse or jacket, and are marked on a commercial pattern. When the garment edges are overlapped and fastened, the centre lines should match.

On a vertical buttonhole the button is positioned in 1/8 in (3mm) down from the top. On a horizontal buttonhole the button sits at the end of the buttonhole, so it must be positioned in 1/8 in (3mm) beyond the centre front line, so that when the garment is fastened the buttons lie directly along the centre.

Place your pattern piece on top of your garment, matching the centre front line. Mark the buttonhole positions at each end, with pins placed at right angles to the buttonhole. Remove the pattern piece, but leave the pins in position. Mark a line between the pins with either a chalk pencil or a line of basting stitches.

Stitching buttonholes

Most modern machines have built-in mechanisms that stitch buttonholes either semi-automatically or fully automatically, so there is no need for you to change the needle position or to pivot your fabric manually. However, older sewing machines may ask you to hand-guide the buttonhole, so please check your manual.

Working a semi-automatic buttonhole

A semi-automatic or sliding buttonhole foot has a gauge down the left-hand side to measure the buttonhole length. Before stitching you will need to mark your buttonhole position and move the slide so that the lower mark on the slider is even with the start of the buttonhole marking on your garment. Draw both threads to the left under the foot.

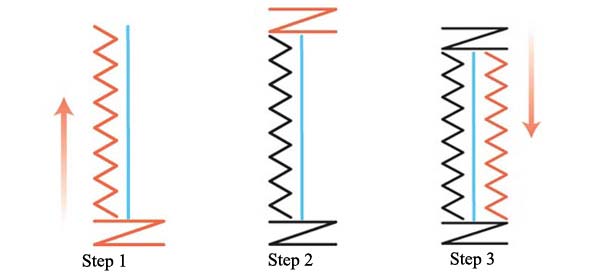

1. Set your machine the first stage of buttonhole; you may have to turn your stitch selector or press a memory button on your machine to stitch each part of the buttonhole, so check your manual. Start stitching — the machine will make the first bar tack. Stitch backward up the left-hand side of the buttonhole, stopping at the top mark. (See image below)

2. Press the memory button or move your dial to stitch the next bar tack. (See image below)

3. Finally, stitch down the remaining side of the buttonhole. (See image below)

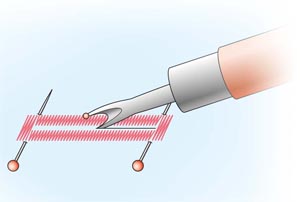

4. Place a pin at each end of the buttonhole just before the bar tacks, to protect them.

Using a seam ripper, carefully slit down the centre of the buttonhole between the pins.

TIPS

If you have mislaid your sewing machine manual, the Internet is a good place to look for advice on sewing machine processes, such as working a buttonhole.

Practice making and slitting buttonholes on scrap fabric before you attempt to work them on your actual garment, to ensure you have the correct size and your stitches are well balanced.

On thicker fabrics, if you find that your stitching is not dense enough, stitch around the buttonhole a second time, directly over the first stitching. This will also give it extra strength.

Working an automatic buttonhole

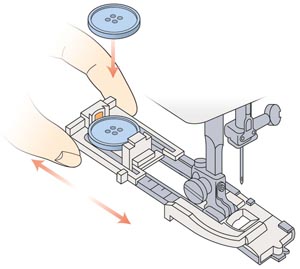

On a fully automatic buttonhole foot, you can set the buttonhole length by placing a button in the button holder, which cuts out the process of measuring beforehand. Double-check your manual for the correct method for your machine.

Attach the buttonhole foot to your machine and set the machine to a square buttonhole. Put the button in the holder, then pull the button holder to the back and adjust it so that the button is held tightly in place. Pull the buttonhole lever down as far as it will go.

Draw both threads to the left under the foot, then place the foot over the buttonhole position, with the needle hole on the foot even with the front end of the buttonhole marking. The machine will complete the whole buttonhole to the correct length, usually all in one operation.

Slit the centre of the buttonhole, as shown for the semi-automatic buttonhole.

My Favourites

My Favourites

Speak Your Mind